WHY WE'RE THE BEST

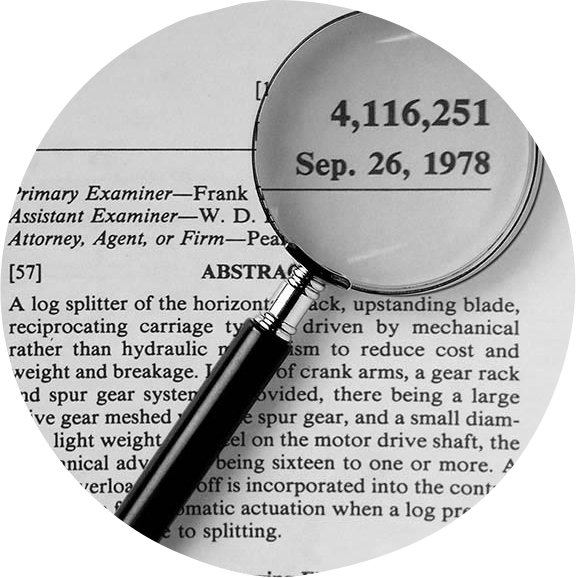

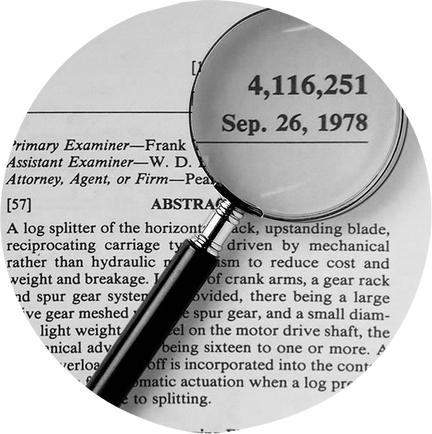

We Own The Patent

That's right. We are the patent holders for the original kinetic log splitter! Ever since, others have tried to imitate us — to change their version from the tried-and-true design that was approved for patent in 1978. We at SuperSplitter, on the other hand, have hardly changed a thing over the years — and we have countless testimonials from the very first buyers that they still own, use and stand by their SuperSplit.

Made In The USA

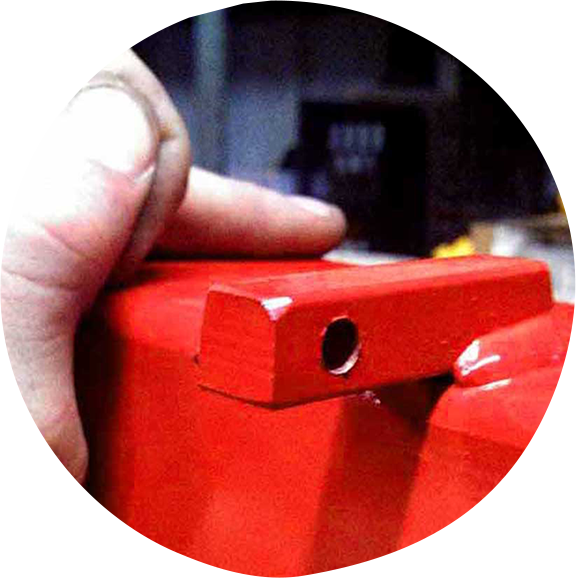

“Made in the U.S.A.” still means something to us. It means pride in our craftsmanship, sweat equity, customer-centered service and quality.

Although most fabrication is done “in house,” the flywheels, rack and pinion gears, clutches, bearings and wheel assemblies are all made in the USA, as well.

Although most fabrication is done “in house,” the flywheels, rack and pinion gears, clutches, bearings and wheel assemblies are all made in the USA, as well.

Made In The USA

“Made in the U.S.A.” still means something to us. It means pride in our craftsmanship, sweat equity, customer-centered service and quality.

Although most fabrication is done “in house,” the flywheels, rack and pinion gears, clutches, bearings and wheel assemblies are all made in the USA, as well.

Although most fabrication is done “in house,” the flywheels, rack and pinion gears, clutches, bearings and wheel assemblies are all made in the USA, as well.

Wondering how it works?

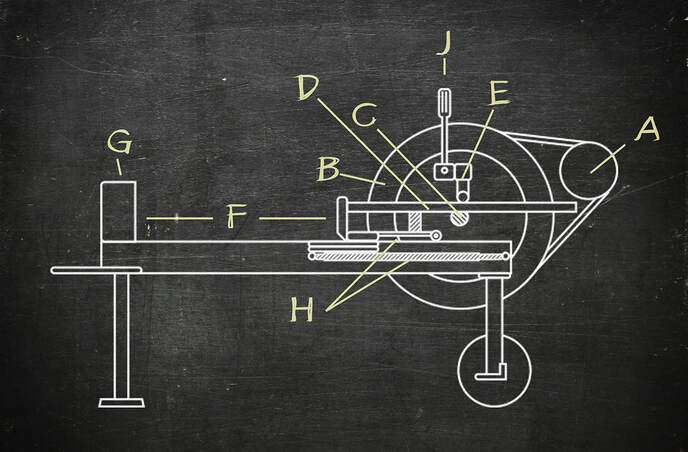

After power is turned on (either gas or electric [ A ] ), the kinetic energy is stored in two revolving flywheels [ B ]. These flywheels are firmly secured to a one-piece pinion gear [ C ]. Because of the flywheel weight and RPM, as well as being mounted on ball bearings and secured to the frame, the pinion gear has tremendous power advantage.

To transmit power from pinion gear to log, a rack gear [ D ] is engaged by a cam-lock assembly [ E ]. The rack gear, now fully engaged and locked in the pinion gear, moves out with a 12 to 24 ton force across the log bed [ F ] into the alloy heat-treated steel blade [ G ]. At the end of the full 24” stroke, the rack is spring loaded upward and backward [ H ], which disengages the cam lock and immediately returns to start position.

For safety reasons, the SuperSplit log splitter is a semi-automatic machine. This means every cycle must be manually activated by lowering and raising the operation lever [ J ] that engages the cam-lock; but after activation, the rack will complete a full cycle. The cycle, however, can at any time be interrupted by simply returning the operating lever to the up position. The flywheel will also stall on overload. Successive cycles may be engaged if necessary in order to drive through particularly large, hard or knotty logs. Flywheel recovery time is about 1/2 second. (If you have ever used a rack type arbor press or swung a heavy maul, you will better understand why the SuperSplit kinetic log splitter principle works so well.

To transmit power from pinion gear to log, a rack gear [ D ] is engaged by a cam-lock assembly [ E ]. The rack gear, now fully engaged and locked in the pinion gear, moves out with a 12 to 24 ton force across the log bed [ F ] into the alloy heat-treated steel blade [ G ]. At the end of the full 24” stroke, the rack is spring loaded upward and backward [ H ], which disengages the cam lock and immediately returns to start position.

For safety reasons, the SuperSplit log splitter is a semi-automatic machine. This means every cycle must be manually activated by lowering and raising the operation lever [ J ] that engages the cam-lock; but after activation, the rack will complete a full cycle. The cycle, however, can at any time be interrupted by simply returning the operating lever to the up position. The flywheel will also stall on overload. Successive cycles may be engaged if necessary in order to drive through particularly large, hard or knotty logs. Flywheel recovery time is about 1/2 second. (If you have ever used a rack type arbor press or swung a heavy maul, you will better understand why the SuperSplit kinetic log splitter principle works so well.

I was truly amazed that in my 35 years of cutting wood, I had not seen nor heard of this type of splitter. I still own my 12-ton hydraulic splitter, but it will soon be on Craig's List. Using the two splitters side by side is like using a screwdriver as compared to using a cordless drill.

Bill Slemp - Hudson, NY

I heard the SuperSplit had a 3-second cycle time. I was skeptical so I rented it to try it out. We have owned our SuperSplit since that weekend in 1984. In that time, it has easily split several thousand cords of wood, and still has the original rack and pinion, and all major components. It is an amazing splitting machine.

John M. Zube - Derry, NH